Textured soy protein (TVP) stands as a versatile and nutritious alternative to meat, offering a meat-like texture and flavor derived from soybeans. The intricate process of crafting textured soy protein involves several key stages:

1. Raw Material Preparation:

Soybeans undergo meticulous preparation, including peeling, hulling, and crushing, ultimately forming soymilk.

2. Defatting:

The soymilk undergoes a defatting process to separate its oil content. Techniques such as centrifugation or ultrafiltration are employed to achieve this separation.

3. Dehydration:

The defatted soymilk transforms into a powdered form through a dehydration process, enhancing its shelf stability and versatility.

4. Extrusion:

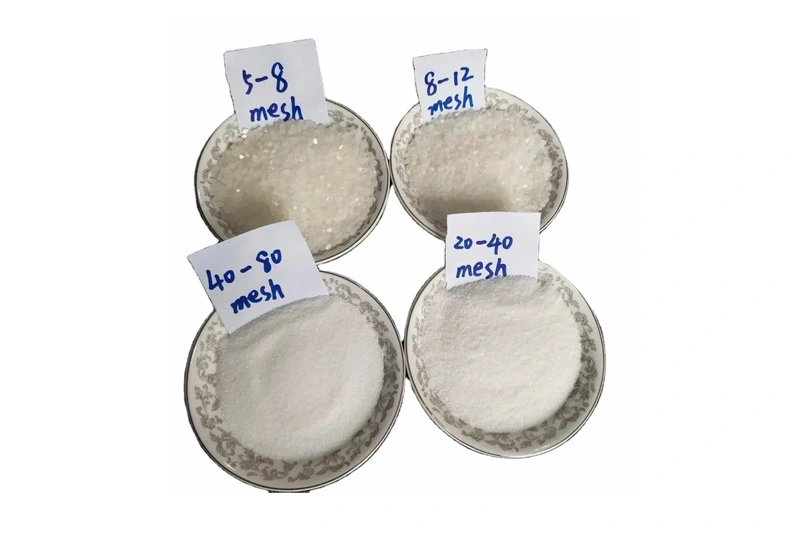

The powdered soy protein takes shape through extrusion, where it is transformed into strands or granules. This crucial step determines the final texture of the product.

5. Seasoning:

To elevate the flavor profile, essential seasonings like salt and spices are added in precise quantities.

The production journey revolves around two core stages: defatting and extrusion. Defatting aims to reduce the fat content and calorie count by removing soybean oil. Extrusion is the art of imparting a meat-like texture to the TSP soy protein.

Controlling extrusion variables such as temperature, pressure, and time allows manufacturers to fine-tune the texture. Higher values in these parameters result in a firmer texture, providing a range of possibilities for culinary applications.

Nutritional Components of Textured Soy Protein

Protein: 20-25%

Fat: 3-5%

Carbohydrates: 30-35%

Fiber: 3-5%

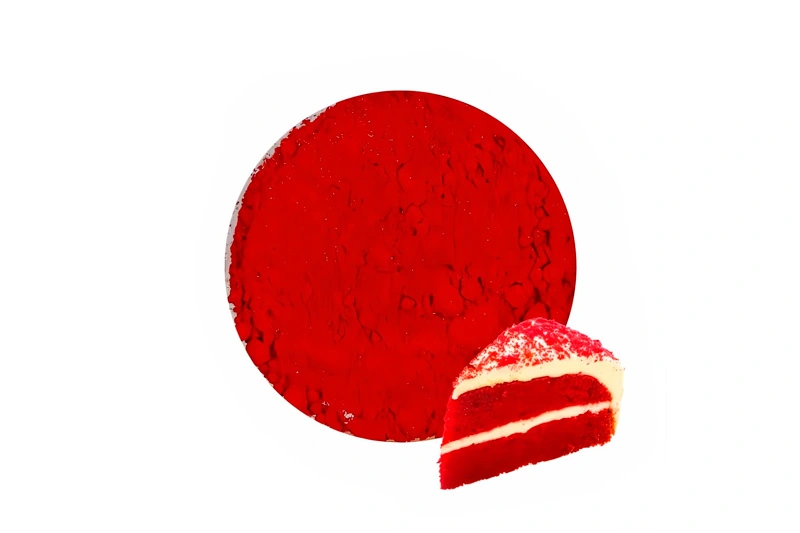

TVP emerges as a protein-rich option, containing all essential amino acids. Its notable fiber content contributes to digestive health and blood sugar control. From vegetarian burgers to Italian meatballs, textured soy protein proves its versatility in a myriad of dishes, catering to the preferences of vegetarians and vegans alike.